Extended DC Technology - Reliability and repeatability

RELIABLE AND FAST MEASUREMENT FOR PTI

ExTDC consists in electrically charging the particles by the diffusion of a high density of ions (positive) created in an ionization chamber by corona effect.

The concentration of charged particles is measured when leaving the sensor, the measurement corresponding to a leakage current per unit of time. This leakage current is proportional to the number of particles (and their specific surface) leaving the sensor per second, it allows to easily find the concentration in number and even in mass of particles.

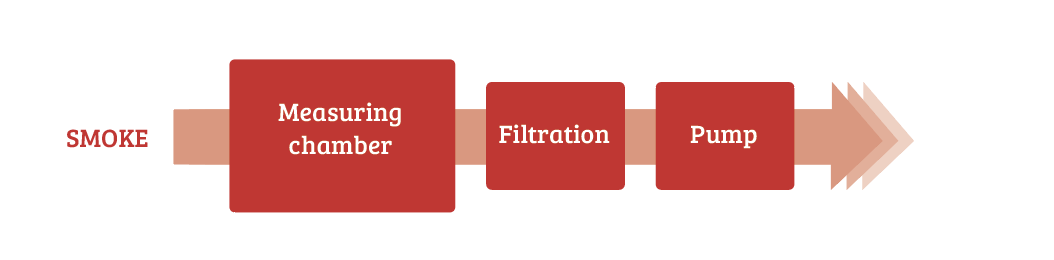

Standard approach

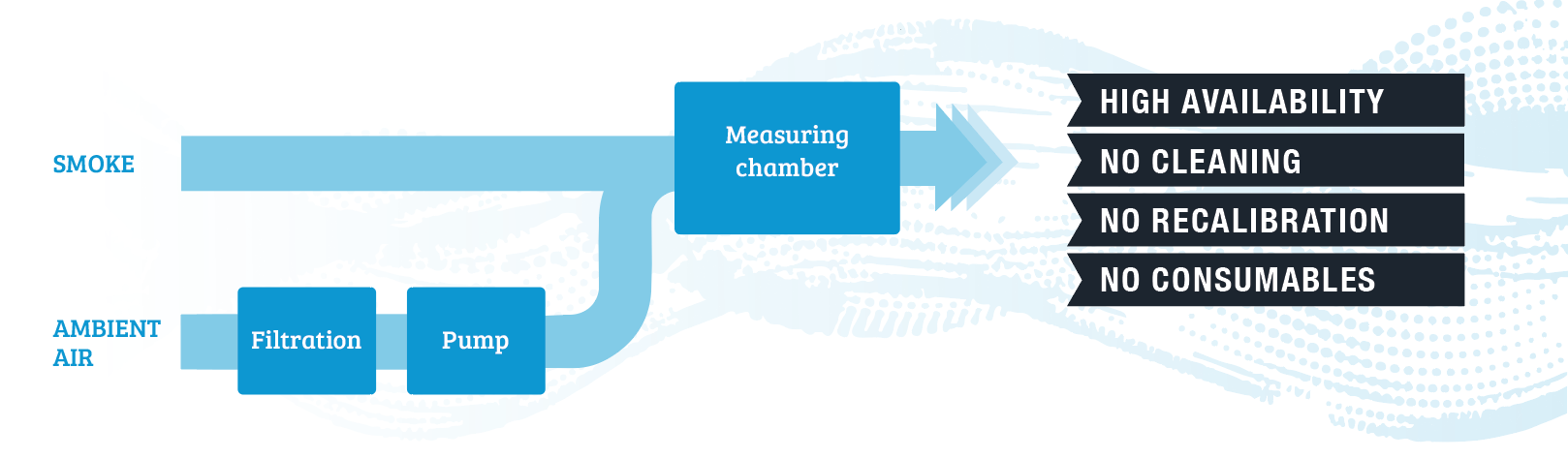

Patented soot-free solution

The smoke particles are sucked in by the Venturi effect thanks to a clean air flow, and are electrostatically charged (15 KV) at the sensor inlet. No risk of sooting the filter and the pump.

Benefits :

- No soot build-up

- No flammable operating liquid

- Insensitive to vibrations

- Independent of position during measurement

- No dilution

- No need of compressed air

CAP3070 Engine Exhaust Particle Counter

Capelec has developed a reliable and fast solution for the efficient measurement of exhaust particle-number concentration.

The CAP3070 uses ExtDC measuring principle without soot clogging. The straight-through design keeps the sensor clean for extended operating time. The measurement is done at idle in less than 30 seconds.