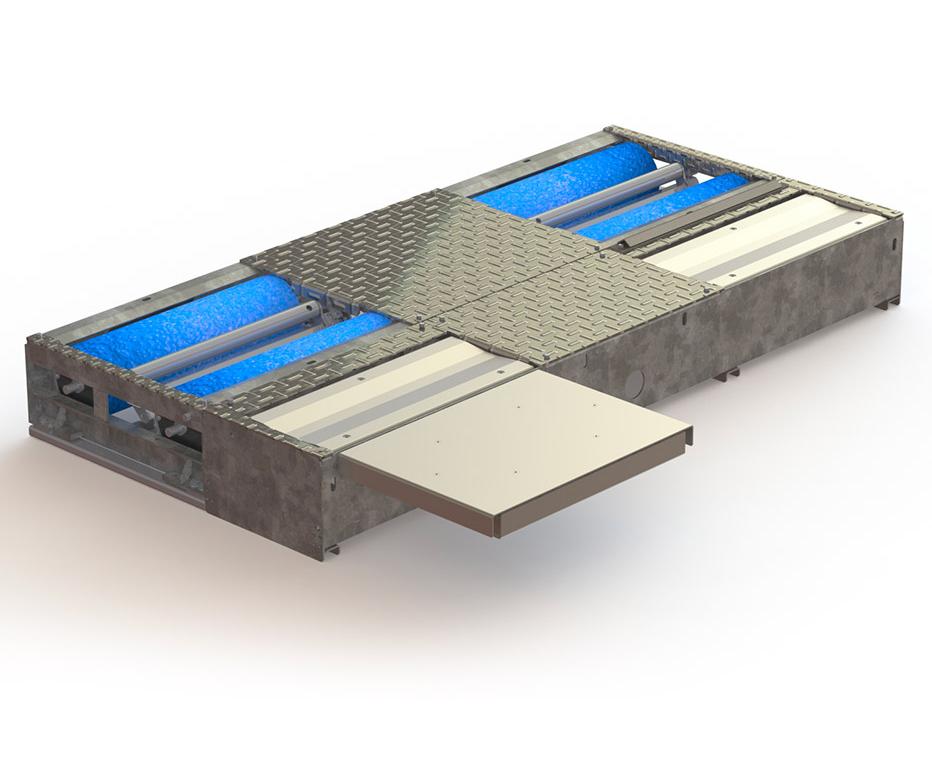

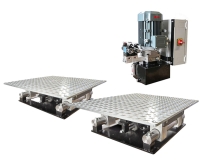

The VL CAP9010 brake tester is composed of 3 modules:

The brake tester: its galvanized frame ensures a good holding in aggressive environments: water, sand, salt .... And its aluminium rollers 3 times lighter than steel rollers facilitate its handling, and do not oxidize. Their Epoxy coating guarantees its performance whatever the weather. Finally, the engine of the Capelec brake tester is resistant and designed to last over time.

The suspension tester: its variator is quiet and resistant. Its wide plate with maximum center distance is a guarantee of productivity, as is the optimal measurement guaranteed by three strain gauges per plate. It has a stop that facilitates positioning. Finally, the PhaseShift and EUSAMA measurement technologies used by the Capelec suspension bench are accurate and universal.

The slip slip tester: it is short to allow the shortest vehicles with narrow center distances to be handled. The rear wheels do not rest on the slip plates during the braking test.

The Capelec multifunction brake tester comes with a remote electrical cabinet for easy maintenance and a CPU board designed and optimized by CAPELEC. Its dimensions enable it to fit into most existing civil works.

The PTI software guides the user in testing process.

And remote control is possible thanks to a wireless screen and a remote control, for greater user comfort.